Tonsley Technical College & Flinders Factory of the Future

Location

Kaurna Country | Clovelly Park SA

Status

Completed 2025

Client

Department for Education

Flinders University

Collaborators

Sarah Constructions

Visuals

Das Studio

Scope

Lead Professional Service Contractor, Architecture, Interior Design

Tonsley Technical College & Flinders Factory of the Future (TTC & FFF) was to be demonstrator in innovation from its very inception. The project represents the future of the building industry, South Australia’s first full mass timber building, and a vessel of industry, research and education all under one roof.

Das Studio consolidated the aspirations of two distinct clients into one cohesive brief, creating the vision, and overseeing the design from concept to delivery.

Proposition

In June 2022, the State Government committed to delivering five Technical Colleges across South Australia, offering senior secondary students direct pathways into future focused careers. Concurrently, Flinders University, was envisioning a Factory of the Future, which would bring together innovation, Industry 4.0 technologies, research and training in advanced manufacturing to strengthen the state’s future industrial capability.

Das Studio were integral in bringing together the joint interests of the State Government and Flinders University, and explore a first-of-its-kind hybrid facility.

Place

Located in the Tonsley Innovation District, pivotal in transforming South Australia’s modern manufacturing landscape, TTC & FFF at Lot 94 is an essential part of a larger vision that has been evolving for decades. An instrumental piece in de-industrialising the precinct, the landscaped edge mediates the threshold between precinct and building, creating relief and re-greening the area.

TTC + FFF is targeting 5-Star GreenSTAR and WELL certification, a disruptor that sets the tone for the future construction industry being housed within.

For People and Planet

A Mass Engineered Timber (MET) structure was chosen to actively flip the narrative of typical constructions methods, renowned for being time, resource, and energy intensive.

MET produces minimal CO2 in manufacture, and sequesters CO2 throughout its entire lifecycle, all the way from forest to building. It vastly decreases onsite build time through prefabrication, and demonstrates an alternative to traditional structural typologies.

Sourced from South Australian, Victorian and Tasmanian forests, it also supports local supply chains. Early trade involvement allowed sharing of knowledge and interrogation of traditional processes from the design’s infancy.

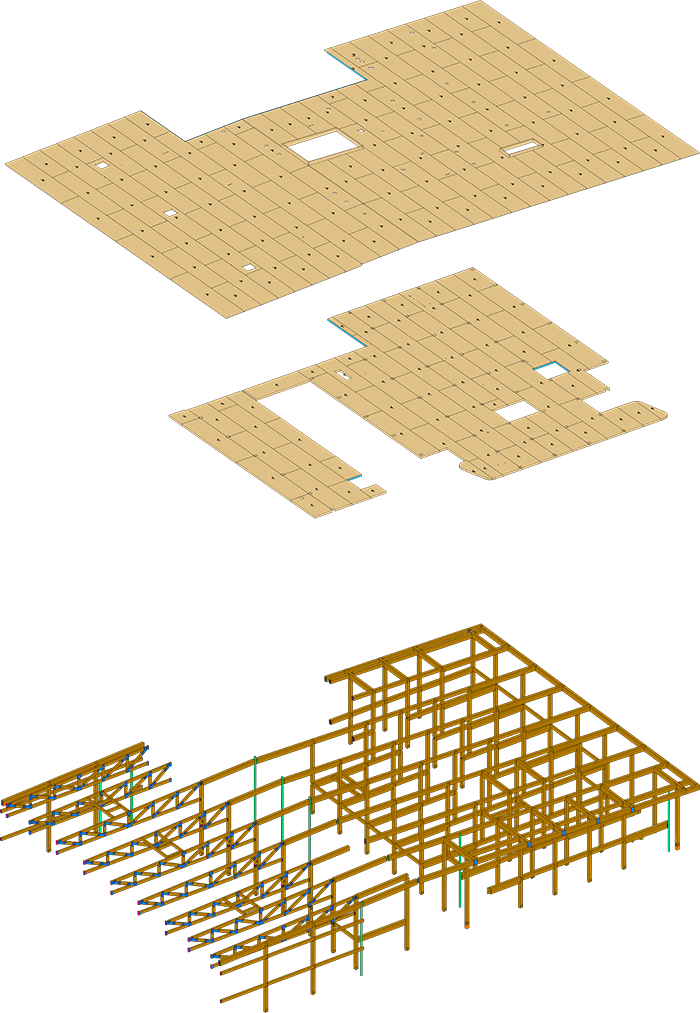

The project’s 433 column, beam and truss components are made of Glue Laminated Mass Timber (GluLAM). If you lined up all the pieces of timber end-to-end, they would stretch for 99 kilometers. The volume of timber used within the project regenerates every two minutes within sustainably managed Australian forests. The roof and floor structures are comprised of 5303m2 of Cross Laminated Timber (CLT) panels manufactured in Tarpeena, in our state’s south-east.

By replacing typical steel and concrete members with timber, the entire building captures the equivalent of over 700,000kg of CO2.

The construction also incorporates 30% Flyash concrete, made from a byproduct of coal combustion, reducing reliance on energy-intensive cement.

Make Better

Spatially and visually, the building converges on a central Village Square. As a key programming move, and symbolic of the two organisations coming together, the space is geared up for hosting wider industry engagement.

Designed to be an educational resource long into its lifespan, the entire building supports learning through observation, with the structure and services on display. To complement the timber frame, the project team selected materials that are honest, minimally processed, and support circularity, reinventing the use of industrial elements.

A soft white perforated steel veil wraps the façade, a permeable mediator at the building’s edge and a signifier of place within the industrial precinct. Standardised, punched out and folded, it is emblematic of the very processes which have occurred on this site across its history, manufacturing more than a million vehicles over five decades.

The building philosophy highlights Das Studio’s mission to Make Better: make with joy, make generously, make the way, and make together.